VAS Ribbed Reinforcing Steel Bar

VAS ribbed reinforcing steel bar is a key construction material, manufactured to high-quality standards to meet the stringent technical requirements of the construction industry. The product comes in long, round bars with raised ribs on the surface, enhancing adhesion to concrete and ensuring strong, durable structural integrity over time.

VAS ribbed steel bars are widely used in both residential and industrial projects, including:

Residential buildings

High-rise buildings and apartments

Bridges, roads, and infrastructure projects

Factories and prefabricated steel buildings

National key construction projects

Key Advantages:

✅ High tensile strength

✅ Excellent adhesion to concrete

✅ Rust-resistant and durable in all weather conditions

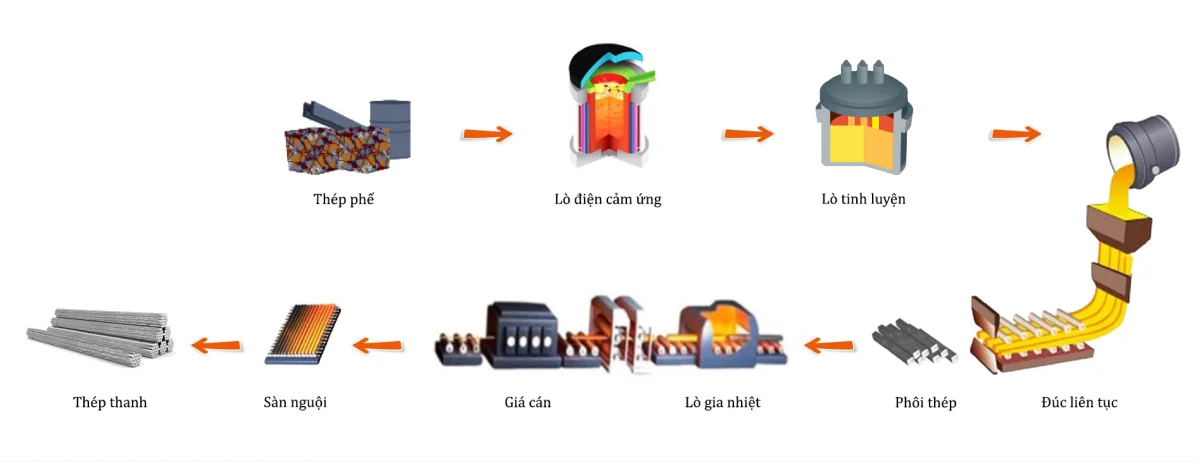

✅ Manufactured on advanced production lines with strict quality control

Standards: TCVN 1651-1:2008

| Nominal Diameter (mm) | Cross-sectional Area (mm²) | Unit Weight (kg/m) | Unit Weight Tolerance (%) |

|---|---|---|---|

| D10 | 78.5 | 0.617 | ±6 |

| D12 | 113 | 0.888 | |

| D14 | 154 | 1.210 | ±5 |

| D16 | 201 | 1.580 | |

| D18 | 254.5 | 2.000 | |

| D20 | 314 | 2.470 | |

| D22 | 380.1 | 2.980 | |

| D25 | 491 | 3.850 | ±4 |

| D28 | 616 | 4.840 | |

| D32 | 804 | 6.310 | |

| D36 | 1017.9 | 7.99 |

Chemical Composition (%)

| Standard | Steel Grade | Chemical Composition |

|---|---|---|

| TCVN 1651-2:2018 (Vietnam) | CB 300-V | _ |

| CB 400-V | C: 0.29 max, Si: 0.55 max, Mn: 1.8 max, P: 0.04 max, S: 0.04 max, Carbon Equivalent: 0.56 max | |

| CB 500-V | C: 0.32 max, Si: 0.55 max, Mn: 1.8 max, P: 0.04 max, S: 0.04 max, Carbon Equivalent: 0.61 max | |

| JIS G 3112:2010 (Japan) | SD 295A | _ |

| SD 390 | C: 0.29 max, Si: 0.55 max, Mn: 1.8 max, P: 0.04 max, S: 0.04 max, Carbon Equivalent: 0.55 max | |

| ASTM A615/A615M-18e1 (USA) | Gr40 (300) | _ |

| Gr60 (420) | _ | |

| BS4449:1997 (UK) | Gr 250 | C: 0.25 max, P: 0.06 max, S: 0.06 max |

| Gr 460 | C: 0.25 max, P: 0.05 max, S: 0.05 max |

Mechanical Properties

| Standard | Steel Grade | Mechanical Properties | Bending Capacity |

|---|---|---|---|

| Yield Strength (N/mm²) | Tensile Strength (N/mm²) | ||

| TCVN 1651-2:2018 (Vietnam) | CB 300-V | 300 min | 450 min |

| CB 400-V | 400 min | 570 min | |

| CB 500-V | 500 min | 650 min | |

| JIS G 3112:2010 (Japan) | SD 295A | 295 min | 440 min |

| SD 390 | 390-510 min | 560 min | |

| ASTM A615/A615M-18e1 (USA) | Gr40 (300) | 280 min | 420 min |

| Gr60 (420) | 420 min | 620 min | |

| BS4449:1997 (UK) | Gr 250 | 250 min | 287 min |

| Gr 460 | 460 min | 483 min |

.jpg.webp)